Breaker plate is to support the screen pack and reduce screw beat. Also called polymer filter or melt filter screen.

Extruder Screens Ensure Plastic Processing A Clean Extrusion

The function of the screen pack in the extruder is to offer a pure and clear extrusion effect to remove unwanted particles.

. Dorstener Wire Tech has over 15 years experience in manufacturing extruder screens and. Rowe Equipment can provide a numerous types of mesh combinations in order to match your. The fine mesh Dutch Weave Wire Cloth Layer together with a Plain Weave Square Mesh support layer forms screen packs are used for.

Polymer and fiber processing requires a wide range of filters and filter media for processing finishing and recycling the materials. Multilayer extruder screen pack is made from several screens of different mesh sizes by welded them together. Finer screens will need an additional support screen to avoid screen.

Their edges styles cover spot welded edges and aluminum framing around the spot welded edges. Screen pack but also serves as a mechanical seal between the barrel and the adapter to the die. Their edges styles cover spot welded edges and aluminum framing around the spot welded edges.

In plastic extrusion stainless steel extruder screen is designed for PP PE and other plastic hot-melt extruding processes. Extruder screens can be made with both one layer of wire mesh or multiple layers. 8 30LD Performance LLDPE Dowlex 3310 285.

Our fabricating facility located in Hickory North Carolina can fill your extruder screen requirements in a prompt and economical fashion. The screens in front of the finest screen are used to catch the larger particles to extend the life of the screen pack and to make the screen pack more rigid. The Nordson Screen Pack is designed with all our knowledge of polymer processing and is.

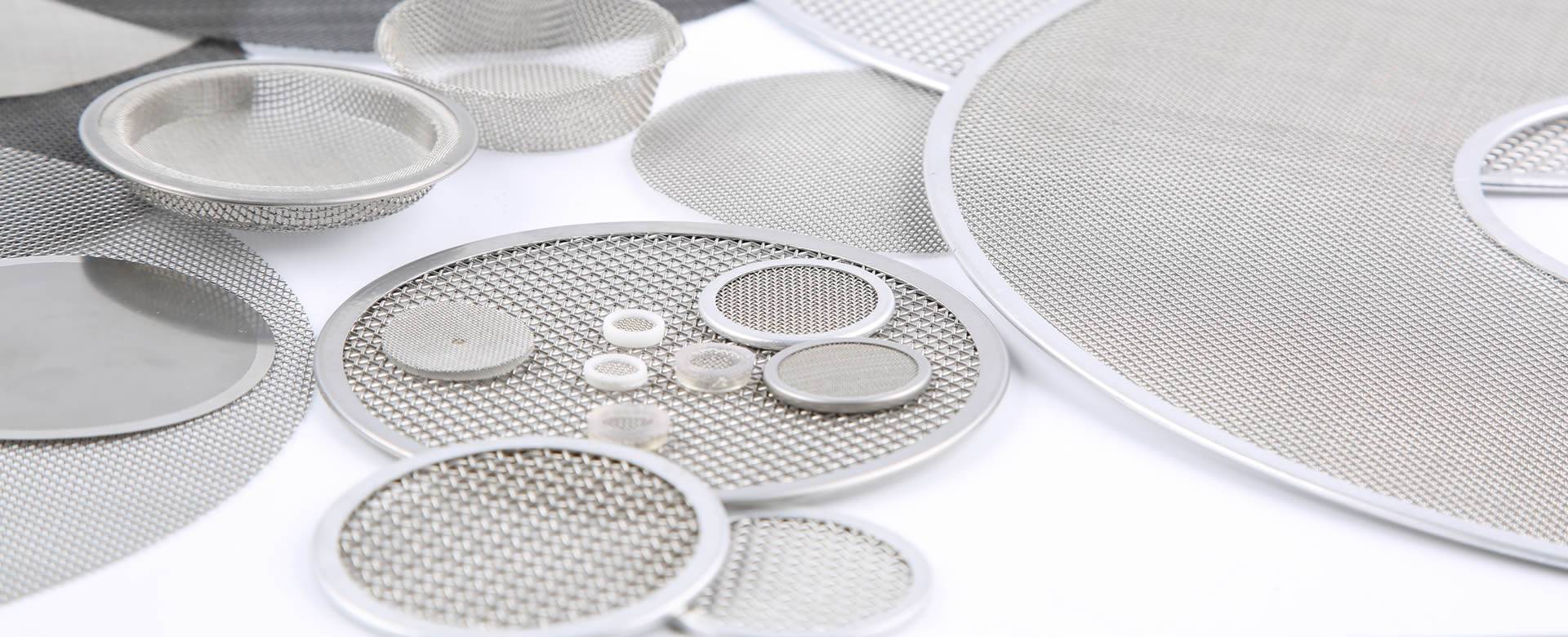

Extruder Screen Mesh packs are mainly made from high quality SS 316 SS304L meshes ranging from 4 mesh to 500 mesh up to 5 microns and used for Plastic and Rubber Industry. Extruder screen packs specification. Extruder screens are manufactured to lots of different specs.

A single-layer is used when virgin material with few impurities is being processed. Cylindrical extruder screen is widely applied in extrusion or filtration process in petrochemical pharmaceutical rubber and plastic industries. Standard Filson extruder filter screens are made of SS 304 SS 316L with a screen pack mesh size of 20-150 mesh.

The number and location of spot welds can be customized for your process. LLDPE Dowlex 3310 Conventional vs. Extruder screw design high output extruder output Screw and Barrel Wear It is often difficult to determine when to replace or repair a worn screw andor barrel.

Also called polymer filter or melt filter screen. 2 3 4 5 layers or other more layers. Extruder screen pack is durable and rigid useful in fine extrusion process for prevention impurities also useful for water treatment plant.

Most packs have the coarsest screen up against the breaker plate to support the others but putting it in backward also works as the bigger particles get caught first and never reach the finest screen. Extruder Screen Pack Design. The Mixing Breaker Plate MBP is similar to the standard breaker plate in that it is stationary in the extruder can hold a screen pack and also reduces screw beat.

Here is how an extruder screen is made. Also available are spot-welded and aluminum bound screen packs. And the screens are in a symmetrical fashion which prevents the screen pack from accidentally being installed.

Multilayer Extruder Screen packs are the different wire meshes cut to desired shapes and sizes and then assembled properly and spot welded with each other to form multilayer packs. Characteristics of the Extruder 3 Screw Design Considerations 3 Gear Pump 4 Screen Pack and Screen Changer 5 Die Design 5 Sheet Line 6 Cooling and Polishing Rolls for Thin Film 6 Cooling and Polishing Rolls for Thick Film and Sheeting 9 Winding Equipment 10 Static Control 10 Extrusion Conditions 11 Start-Up and Line-Out Procedures 12 Quality. Extruder Screen Mesh packs are mainly made from high quality SS 316 SS304L meshes ranging from 4 mesh to 500 mesh up to 5 microns and used for Plastic and Rubber Industry.

These extruder screen packs are developed for ease of operation better inventory control and process control assurance. JELLIFF CORPORATION can supply a complete range of sizes and shapes of screens in steel and stainless steel. Nordson Screen Pack For an efficient filtration process and to exploit the full potential of the filtration system a state-of-the art filtration medium is essential.

An extrusion screen doing its job. Recommended for LLDPE and engineering resins in extrusion coating applications Also beneficial for lower temperature higher output polyolefin applications Offers superior melting rates and process stability. And customized service is also available according to your screen pack extrusion requirements.

Extruder screens and polymer filters are just two of the varieties of filtration products offered by Dorstener Wire. Extruder Screens Polymer Filters. This pack screen filter is designed to keep away mixing of foreign particles in finally equipped extrusion product.

The holes in the breaker plate are normally 0318 cm 18 in to 0635 cm 14 in with a chamfer designed to give minimal obstruction to material flow. Table 1 Suggested Screw Design for Extrusion of Lubrizol TPUs Extruder Size 381 cm 1 12 in. Screens are often put in as a screen pack with two three or more screens of different meshes.

Extruder Screen Pack Design. Screen packs help ensure your plant uses the same pack each and every time. Multi-layer is used when reground.

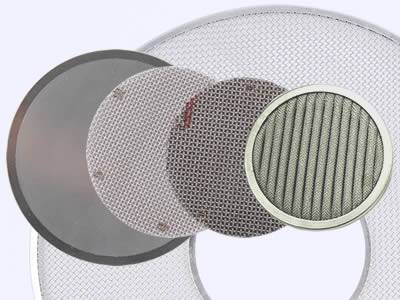

In the different mesh size screens the finest wire screen is in the center of the pack and the larger mesh opening screen is successively placed outer sides. A 20-mesh screen is typically used for the outside of the pack and can support up to a 150-mesh screen depending on the extrusion pressures. 8 30LD Extruder Resin.

However this new device is designed to created strong elongational flows for dispersive mixing by. Extruder Screen Mesh packs are mainly made from high quality SS 316 SS304L meshes ranging from 4 mesh to 500 mesh up to 5 microns and used for Plastic and Rubber Industry. The mesh that makes up the screen will be the exact opening size for your process and the size and shape will be dictated by your machines.

The screen pack also increases backpressure in the barrel Page 2 of 3 techtopic LyondellBasell Technical Tip The Extruder continued Zone 1 325F. - Wire mesh specifications with an appropriate micron rating are chosen. Extruder screen pack design For anyone who is a enthusiast of nail artwork but are certainly not utilized to the numerous coats of acrylic then this kind of design may possibly just perform very well for you.

Extruder Screen The Ultimate Faq Guide Filson Filter

Stainless Steel Extruder Screen Pack Hightop Filter And Strainer

China Extruder Screens And Screen Pack For Filtration And Plastic Extrusion Process China Extruder Screen Extruder Screen Pack

Extruder Screens Ensure Plastic Processing A Clean Extrusion

Get Smart About Screens Plastics Technology

Get Smart About Screens Plastics Technology

Screen Packs For Bkg Screen Changers Maintain Structural Integrity Ensuring Maximum Filtration With Optimum Melt Flow

0 comments

Post a Comment